Brothers Orthodox Tea

Quality through ownership

Total production capacity (annual):

2 Metric Tonnes

Total employees:

15 (including 10 seasonal staff)

Present exporters:

India, China, Germany, France, USA

Total farmers:

1300

Connect with us

About Ilam

Illam is located in the hilly area 600 km (370 mi) east from Kathmandu in the Mechi Zone of Nepal’s Eastern Region. The district covers 1703 km2 (658 sq mi) with a population of 290,254 (as of 2011), and is home to the district’s administrative center and the largest city lying on the lap in the hilly region.

The topography of the Illam District is hilly, with the altitude range from 600 meters to 2500 meters approx. Deumai is a town and Municipality in Illam District in the Mechi Zone of eastern Nepal.

The major produce of the region include Tea, Cardamom, Ginger, Turmeric, Maize, Broom, and Dairy Products.

Our Story

Brothers Orthodox Tea Producers Pvt. Ltd, is located at the Deumai Municipality, Mangalbare Panitar, which is 30 kms West from Ilam in East Nepal and around 1650 m above sea level. The land is known for its bio diversity and natural reserve of herbs and highest quality tea.

Brothers Orthodox Tea Producers Pvt. Ltd was established in 2012 AD and Panitar Tea Producers Group & Farmers was initiated around 1990 with plants derived from high quality tea varieties planted locally by farmers migrating from other villages of Ilam district. The plantation is young and fresh nearing maturity and therefore, the quality of tea is considered very high as compared to many other tea areas of Nepal (young plants have the highest level of aroma and character builds up as the plants age).

The ownership of land and property in such cases reside at a corporate level. The tea plantation at Brothers has been carried out by the local farmers in their own land and therefore, Brothers Tea (Panitar) is an entirely farmer based-production with the ownership of the plantation remaining at the farmer level.

At Brothers we believe that quality can only be achieved by those who have a sense of ownership of the garden because tea quality is defined starting from the leaf that is fed to the factory for processing. Due to this the farmers can therefore grow and harvest only the finest naturally grown leaf for processing as compared to those working for a corporate plantation.

Our Team

Raju Katuwal

Raju has over 20 years experience in Tea farming and for the last 7 years he has been more involved in marketing tea.

Surya Lamichane

Surya has over 10 years of experience in tea processing and factory management.

Objectives

- Ensure consistency in quality / food safety of Panitar Tea collectively using advanced machineries and arrange cost effective shipment to assure competitiveness in the international market to attract volume buyers.

- Support and facilitate tea farmers in organic cum quality enhancing skill to assure quality tea and brand globally by creating a sustainable CSR fund from sales revenue of the project

- Standardize packaging and branding of tea for consumer markets

- Achieve 100% customer satisfaction

Technology & Machinery Installed

Land & Building

- 4800 sq ft of factory building made of bricks & cement, 1st floor used for withering trough and ground floor used for Rolling, Fermentation, Dryer, Grading and Storage

- Ample of land for the project

- Eco friendly building and highly suitable for SPS measures

Sorting / Grading Machines (3 sets)

- 3 sets of machines having capacity to sorting and grading of 200 kg/hr

- Sorting and grading the tea according to weight, length, size, remove stalks and foreign bodies

Withering Trough

- 5 Withering Troughs with the capacity of 1500 kg green leaves per day

Rolling Machines

- 3 different types of rolling machines have been installed that can twist green leaves

Dryer Machine

- 4 feet dryer machine to remove final moisture from leaves

Enzymer & Revolving Dryer

- For making of green tea to remove moisture and fixation and drying of tea leaves

Company details

Annual production capacity

2

metric tonnes (+25MT)

15

employees (including seasonal staff)

130

farmers

Business impact

Unique Features of our Tea

- The quality of the tea produced at an altitude of 1650 m is always better compared to tea produced from leaves from lower altitudes

- All of our tea leaves are plucked by family members of the producers who care for their tea bushes almost as much as they care for their children, ensuring that the tea leaves are exceptionally good for production

- The tea producing area in the hills is located at the base of Mount Kanchenjunga, which is believed to have one of the widest ecosystems and is rich in organic matter

- Most of the tea bushes are free of any chemicals, ensuring that the tea is completely organic with a unique taste, and contains abundant medicinal properties such as antioxidants

Types of Tea Produced

White Tea

Processing Method: Use only bud, 10 hrs withering, slightly hand rolled and dryer

Characteristic: Pale yellow liquor, fruit flavor and sweet taste; first flush is good to make silver tips

Golden Tea

Processing Method: Use one leaf and bud, 9 hours withering, machine rolled, 7 hours of fermentation then dry

Characteristic: Dark liquor, honey flavor sweet taste; second flush is good to make golden tea

Pearl Green Tea

Processing Method: Use two leaf and fixation on enzymer machine, rolled on machine, use shaping machine and rolled with dry

Characteristic: Himalayan taste and aroma

Black Tea

Processing Method: Use two leaf and bud, 10-14 hours withering, machine rolled 1-3 hours fermentation as per required, dry and sorting by machine

Characteristic: Quality depends as per season; Himalayan aroma and taste

Silver Tips

Processing Method: Use only bud, 10 hours withering, slightly hand rolled and dryer

Characteristic: Pale yellow liquor, fruit flavor and sweet taste; first flush is good to make silver tips

Golden Tips

Processing Method: Use two leaf and bud, 10-14 hours withering, machine rolled 1-3 hours fermentation as per required, dry and sorting by machine

Characteristic: Dark liquor, honey flavor sweet taste; second flush is good to make golden tips

Green Tea

Processing Method: Use two leaf and but, fixation on enzymer machine, rolled on machine, drying on revolving machine and hand sorting

Characteristic: Quality depends as per season; Himalayan aroma and taste

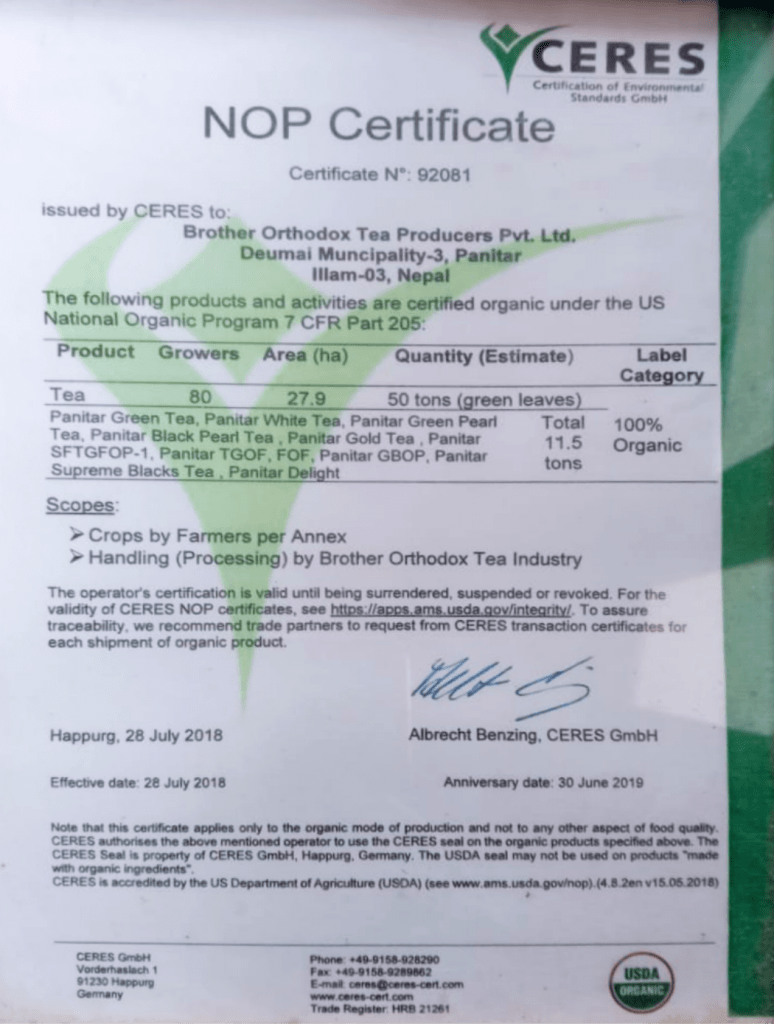

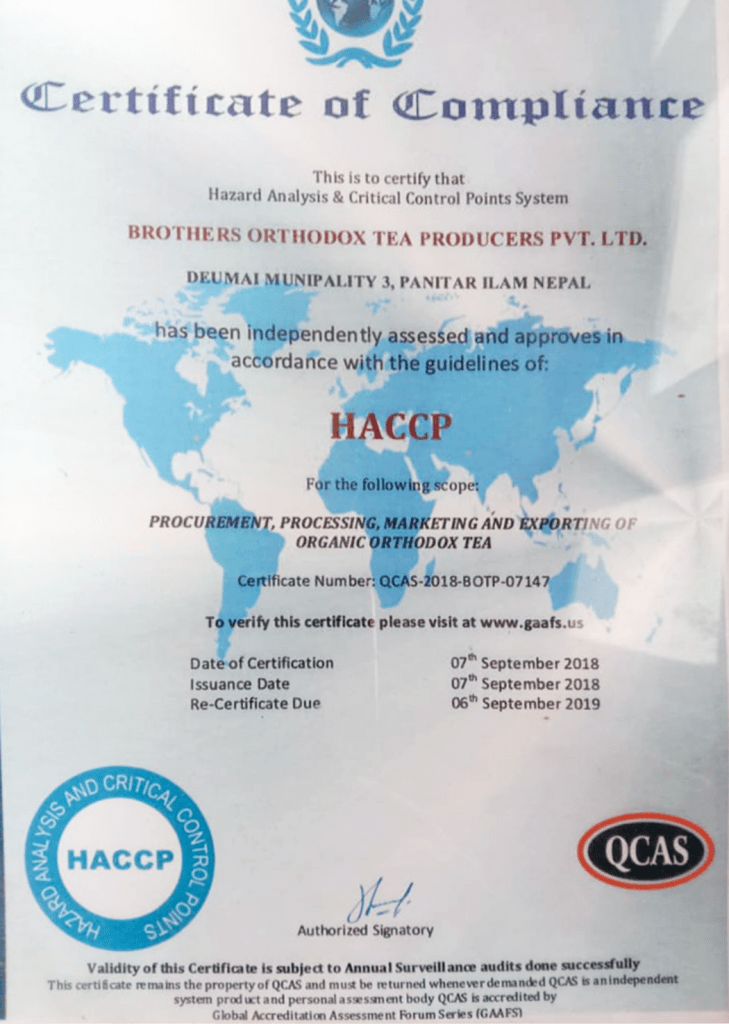

Certifications

Global Presence / Main Export Destinations

Proudly collaborating with ITC

Being part of the ITC Sustainability Marketplace program, funded by USAID, has been a great opportunity for us. The marketing support that we have received from the program has helped us reach a global audience.

Our organization receiving the following support:

- Strategic Marketing Help

- Creation of several Marketing collaterals including pitch decks and landing pages

- Social Media Marketing